TECHNOLOGY PLASTOMECH P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECHNOLOGY PLASTOMECH P LTD.

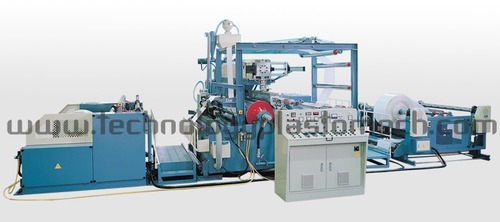

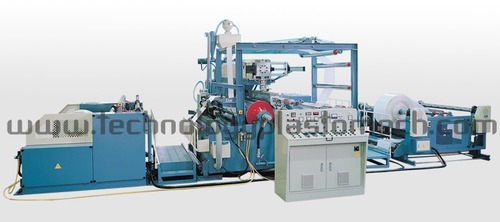

Extrusion Coating Lamination Plants

Since our inception, we have been affianced in offering high performance Extrusion Coating Lamination Plant. We are backed by a team of dexterous professionals, who aid us in providing a unique design to these plants as per their application in industries. To maintain the quality and eradicate any kind of defect, our quality controllers strictly test them against various quality parameters. Owing to some of their striking features, these are broadly demanded in the market.

A large portion of woven sacks – 30 to 40 percent – is produced with coating, because coated sacks provide much better protection of the contents from dust and especially from moisture. Coated fabric also offers better printability. However, uncoated sacks are preferred for some applications, especially for filling goods that require breathable fabric.

TPPL multi-function Extrusion coating laminating machine is developed continuously by ourselves, based on our production experience of more than Fifteen years. It is characterized by advanced technique, reliable quality, easy to operate, and high automation, which is used widely in the industries of chemical, petrochemical, cement, sugar, salt, Grain and wheat, Animal feed, Commodity items, metallurgy and mining and general purpose packaging, storage and transportation of many kinds of materials. The line uses PP or PE as raw material, through the flow-casting coating and lamination technology, achieving single-sided/ double-sided coating or paper-plastic lamination with substrates (plastic woven fabric), to produce coated or laminated products. The line is equipped with advanced electrical and mechanical devices throughout the whole production flow from substrate unwinding, lamination to winding, to achieve single control and group control. The dual-station unwinder uses automatic web guiding control for substrates, and brakes for surface tension control of substrates, achieving pneumatic splicing and non-stop roll changing. The laminator is equipped with preheating roll (optional) for preheating and drying of substrates. Laminating roll, silicon rubber roll and press roll are of dual-interlayer forced water cooling structure, with excellent cooling effect. The dual-station winder adopts constant-tension surface friction winding, pneumatic transverse cutting, roll changing without shutdown, and equipped with adjustable edge-trimming device, edge-strip blowing device, and length counting device.

Features:

High performance

Operational fluency

Low power consumption

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.